Cable Construction and Materials

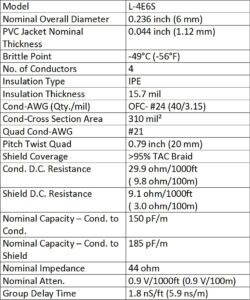

The quality of materials used in an XLR cable can greatly impact its performance. High-quality conductors, such as oxygen-free copper (OFC), ensure optimal signal transmission and minimal signal loss. A durable outer jacket and shielding materials will also protect the cable from physical damage and interference. The Mogami Gold Studio Microphone Cable and Canare L-4E6S Star Quad Balanced Microphone Cable are excellent examples of cables with high-quality construction.

Conductors

The conductors in an XLR cable play a crucial role in transmitting the audio signal. They should be made of high-quality materials that ensure optimal signal transmission and minimal signal loss. Oxygen-free copper (OFC) is the most common material used for conductors in high-quality XLR cables due to its excellent conductivity and resistance to corrosion.

Insulation

Insulation is essential for protecting the conductors and minimizing signal interference. High-quality XLR cables should have insulation made from materials like polyethylene or PVC, which provide a good balance of flexibility and durability.

Shielding

Effective shielding is necessary to minimize electromagnetic and radio frequency interference that can degrade audio quality. Common shielding materials include braided copper, foil, or a combination of both. A well-shielded cable, like the Canare L-4E6S Star Quad Balanced Microphone Cable, will ensure a clean audio signal with minimal interference.

Outer Jacket

The outer jacket of an XLR cable provides physical protection and durability. It should be made from rugged material, such as PVC or rubber, that can withstand regular use and resist abrasion, cuts, and other potential damage.

Noise Reduction and Interference Protection

One of the most important factors when choosing an XLR cable is its ability to reduce noise and protect against interference. A well-shielded cable will minimize electromagnetic and radio frequency interference, ensuring a clean audio signal. With its unique star quad design, the Canare L-4E6S Star Quad Balanced Microphone Cable is a great example of a cable that offers excellent interference protection.

Electromagnetic Interference (EMI)

Electromagnetic interference (EMI) can cause unwanted noise in your audio signal. High-quality XLR cables should be designed to minimize the effects of EMI, often through the use of effective shielding materials and construction techniques. Braided or spiral shielding is commonly used to protect against EMI.

Radio Frequency Interference (RFI)

Radiofrequency interference (RFI) can also degrade audio quality. To protect against RFI, some XLR cables incorporate additional shielding, such as foil shielding, or utilize specialized construction techniques like the star quad design found in the Canare L-4E6S Star Quad Balanced Microphone Cable.

Flexibility and Mobility

You may require a more flexible mobile cable depending on your specific needs. For instance, musicians and sound engineers who frequently travel or perform live may benefit from a lightweight, flexible cable like the Pro Co EXM-20 Excellines Microphone Cable. Keep in mind that some cables may sacrifice durability for flexibility, so it’s essential to find a balance that suits your requirements.

Cable Thickness

Cable thickness can impact a cable’s flexibility and weight. Thinner cables tend to be more flexible and lightweight, making them easier to transport and maneuver during performances. However, they may be less durable and more susceptible to damage. It’s important to find a cable with a thickness that balances flexibility, weight, and durability for your specific needs.

Cable Length

The length of your XLR cable is another factor to consider when evaluating flexibility and mobility. Longer cables can provide more freedom of movement but may also introduce signal loss and be more challenging to manage. Choose a cable length that suits your setup and allows for comfortable use without sacrificing audio quality.

Coilability

Coilability refers to how easily an XLR cable can be wound up for storage and transport. Some cables, like the Pro Co EXM-20 Excellines Microphone Cable, feature a more flexible design that allows for easy coiling and uncoiling, making them ideal for mobile performers or those with limited storage space.

Price and Value

The price of an XLR cable can vary greatly, and it’s essential to find one that offers the best value for your budget. While some cables, like the Mogami Gold Studio Microphone Cable, come at a higher price point, their performance and durability can make them a worthwhile investment. On the other hand, more budget-friendly options like the Hosa HMIC-010 Pro Microphone Cable still provide reliable performance at a more affordable price.

Budget Considerations

When selecting an XLR cable, it’s crucial to set a budget and prioritize the features that are most important to you. Be prepared to spend more for a cable with higher-quality materials and construction, but don’t overlook more affordable options that still offer excellent performance.

Long-Term Investment

High-quality XLR cables can be a long-term investment, as they typically offer better durability and longevity compared to their lower-priced counterparts. If you plan to use your cable frequently or in demanding environments, it may be worth spending more upfront to save on potential replacement costs in the long run.

Price vs. Performance

While it’s essential to consider price when selecting an XLR cable, remember that the cheapest option may not always provide the best performance. Weigh the benefits of each cable against its cost to determine the best value for your needs.

Specific Use Cases

Some XLR cables are designed with specific use cases in mind, such as the Audio-Technica AT8314 Premium Microphone Cable, which focuses on vocal clarity. Consider the primary purpose of your cable when making your selection, and choose one that aligns with your specific needs.

Studio Recording

For studio recording, look for cables that offer excellent sound quality and minimal noise interference. High-quality materials and construction are particularly important in this setting, as they will contribute to your recordings’ overall clarity and fidelity.

Live Performances

Live performance situations may require cables with greater flexibility and mobility, and durability to withstand the rigors of regular use on stage. Look for cables that are easy to coil and uncoil, and prioritize options with robust outer jackets and connectors that can withstand frequent plugging and unplugging.

Broadcasting and Streaming

Consider cables with superior noise reduction and interference protection for broadcasting and streaming applications. These features will help ensure a clean audio signal, which is particularly important when transmitting audio to a live audience or capturing audio for post-production.

Connectors and Compatibility

The connectors on your XLR cable should be compatible with your microphone and audio equipment. Most professional-grade microphones use a three-pin XLR connection, but it’s essential to verify the specific requirements of your gear before making a purchase. Additionally, consider the quality and durability of the connectors, as they play a vital role in maintaining a secure connection and optimal signal transmission.

Connector Type

Most XLR cables designed for microphones feature a male connector on one end and a female connector on the other. However, some specialized applications may require different connector types, such as XLR to TRS or XLR to RCA. Ensure that the connectors on your chosen cable are compatible with your equipment.

Connector Quality

High-quality connectors are essential for maintaining a secure connection and optimal signal transmission. Look for connectors made from materials like gold-plated brass or nickel, which offer excellent conductivity and durability. For example, the Mogami Gold Studio Microphone Cable features gold-plated connectors that ensure reliable performance and a long lifespan.

Connector Durability

In addition to the connector materials’ quality, consider the connectors’ overall durability. Strain relief mechanisms, such as rubber or metal spring guards, can help prevent damage to the cable and connectors when they are subject to stress or tension during use.